CLT Buildings

CLT Buildings

CLT Buildings: Sustainable, Strong & Innovative

What are CLT Buildings?

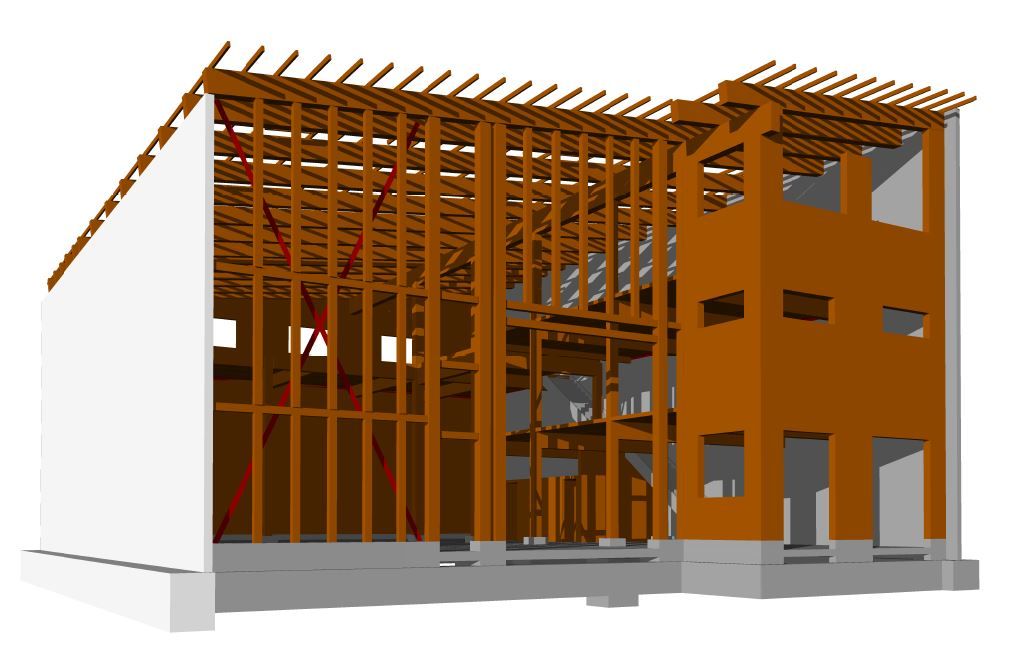

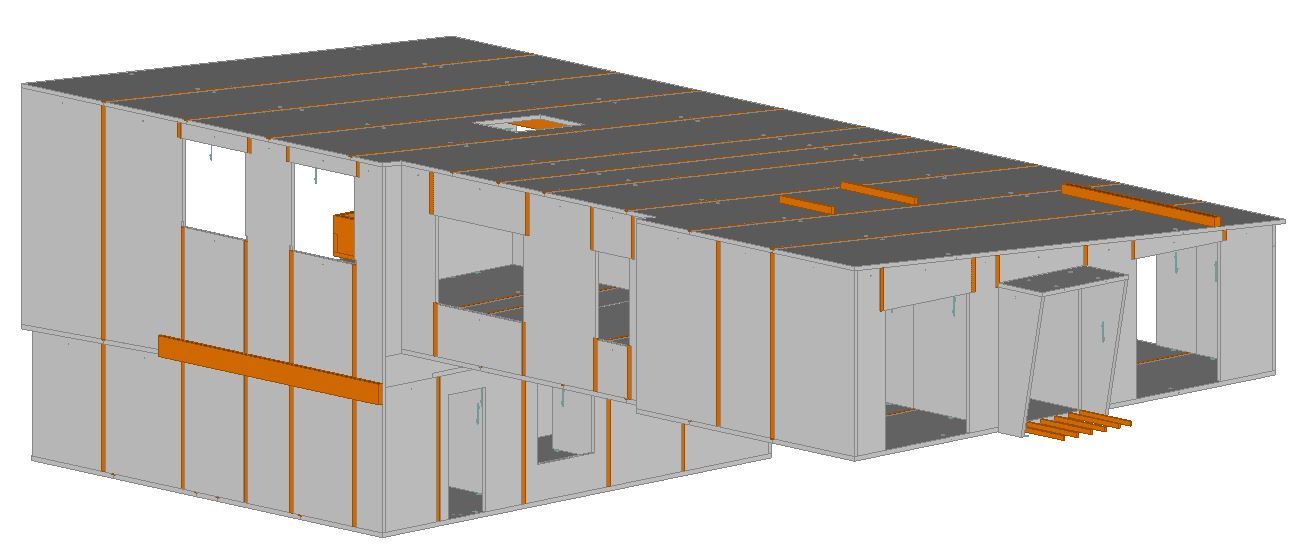

CLT buildings, or Cross Laminated Timber (CLT) constructions, represent the future of sustainable architecture. Made from CLT panels, these structures offer strength, durability, and eco-friendly benefits that traditional materials like steel and concrete cannot match. Whether you’re looking for CLT home designs or CLT house construction, cross laminated timber is a versatile choice.

We have extensive experience in the use and application of CLT and Glulam products. Our expert team can provide support and services through all stages of the project, including:

- Initial CLT design and planning

- CLT engineering design and certification

- Material specification (CLT panels, CLT wood, CLT lumber)

- Wall, floor, ceiling and roof build up (CLT construction details)

- Drafting services

- Pricing (comprehensive CLT panels cost)

- Supply of products, accessories and connections (cross laminated timber manufacturers)

- Transport and customs clearance

- Installation (CLT timber construction & CLT installation)

- Connection details and sealing

- Commissioning

SCS has completed a number of CLT buildings. Please contact SCS for more information on our CLT and Glulam services, to find out how we can assist on your next project.

Why Choose Cross Laminated Timber?

- Sustainability: cross laminated timber is sourced from responsibly managed forests, making it a renewable and environmentally friendly building material

- Strength & Durability: With its layered design, CLT timber construction provides excellent load-bearing capacity, making it suitable for multi-story buildings and residential homes alike.

- Precision & Efficiency: CLT installation is faster and more efficient than conventional building methods due to prefabricated CLT panels that fit together seamlessly, reducing construction time and labour costs.

- Thermal & Acoustic Performance: Cross laminated timber offers superior insulation, reducing energy costs while also providing excellent soundproofing properties for a quieter living space.

CLT Home Designs & Construction

From CLT house construction to large-scale commercial buildings, CLT timber offers unparalleled design flexibility. Architects and builders worldwide are incorporating CLT home designs to create stylish, modern, and energy-efficient homes that stand the test of time.

CLT Panels for Sale

If you’re considering using cross laminated timber for your next project, we offer high-quality CLT panels for sale. Whether you need panels for residential, commercial, or industrial use, our cross laminated timber manufacturers ensure top-quality materials that meet industry standards.

Find the Best Cross Laminated Timber Manufacturers

Choosing the right cross laminated timber manufacturers is essential for ensuring the longevity and performance of your structure. We work with top suppliers to bring you the highest quality cross laminated timber panels for any project.

Start Your CLT Timber Construction Today

If you’re ready to embrace the benefits of CLT buildings, our team can help you find the right CLT panels, design your dream home, and manage the CLT installation process. Contact us today to learn more about our cross laminated timber constructions and how they can transform your project!

Get a Quote

SCS has extensive experience in the use and application of CLT and Glulam products. SCS can provide support and services through all stages of the project, including:

- Initial design and planning

- Engineering design and certification

- Material specification

- Wall, floor, ceiling and roof build up

- Drafting services

- Pricing

- Supply of products, accessories and connections

- Transport and customs clearance

- Installation

- Connection details and sealing

- Commissioning

Our experienced team at SCS can provide support services for any component of the work and will provide you with advice relating to finishes; for example, surface quality recommendations, paint types or treatments. SCS can also provide information and details for connections (e.g., fixings, screws, brackets etc.) and proper sealing for both acoustic and thermal insulation.

The actual installation process of CLT and Glulam is extremely efficient and straightforward. Engineered wood products are a lightweight material choice compared to concrete panels and masonry construction, resulting in simplified installation and minimal slab and footing requirements. Sophisticated manufacturing processes mean a high level of prefabrication is possible. CNC technology (Computerized Numerical Control), allows openings and penetrations to be cut in factory, to the highest level of precision. The natural workability of timber, also allows for these penetrations to be easily made onsite and for very straight forward connections. Minimal manpower is required on-site, greatly reducing the labour cost of the project. Most CLT and Glulam projects only require 2 carpenters and 1 crane operator on-site, to handle the installation of the building envelope.

Please contact SCS to find out more on our CLT and Glulam design, supply and installation services. We provide full project services to clients in Metropolitan Melbourne, Regional Victoria and Australia wide.